Sandwich panel SP2E X-PIRS Energy

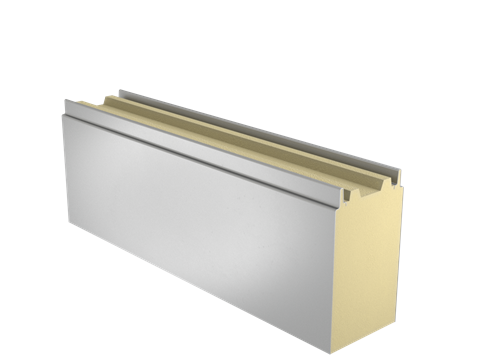

Sandwich panel SP2E X-PIRS Energy is available in thicknesses 120 - 160 mm.

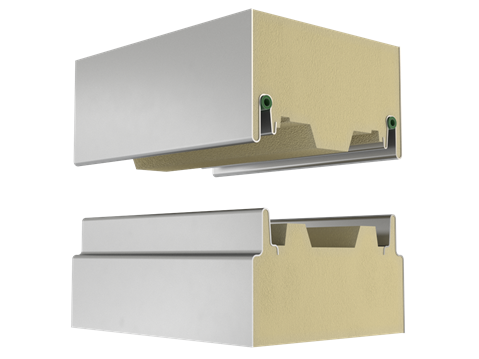

With precise and Ruukki specific manufacturing tolerances, and factory-fitted seals on the panel joints, the Ruukki® Energy panel structure

with its seams forms a very airtight solution. Together with Ruukki Airtightness package it’s possible to achieve excellent airtightness to the entire building. This can decrease energy costs and CO2 emissions up to 30%. Read more on airtightness package. Using Ruukki's solutions you can receive more credits in LEED and BREEAM certification systems.

Low U-value and proper joint design together with wide thickness range make this sandwich panel an ideal solution for cold storage buildings. Innovative technology increasing

strength parameters of the panel provides for load-bearing capacity up to 40% higher comparing to standard solutions.

With excellent reaction to fire and fire resistance values, this panel ensures the highest level of fire safety for buildings and their users.

The core of this sandwich panel is made of rigid, HCFC-free, self-extinguishing and sustainable polyisocyanurate foam (PIR). Its excellent thermal insulation properties allow for the decrease of panel thickness which transfers directly to lower transportation and assembly costs, as well as significant savings of building's life cycle costs.

Optionally, on request, SP2E X-PIRS Energy sandwich panel can be delivered as FM Approved product with a certificate granted by the world-biggest insurance company FM Global. The global certificate received based on 4880 and 4881 standards confirms that a building’s envelope made of these sandwich panels from Ruukki ensures the highest safety level in case of fire or hurricane.

For all needed information about FM Approved panels, please contact Ruukki Sales.

Application:

- External walls (standard fix)

This product is optionally available with following sustainable features:

- Steel facings made of recycled steel (SSAB Zero) for significantly lower CO2 emissions and high circularity (Ruukki LowCarbon)

- Air tightness package for lower CO2 emissions during building use

The information on our website is accurate to the best of our knowledge and understanding. Although every effort has been made to ensure accuracy, the company cannot accept any responsibility for any direct or indirect damages resulting from possible errors or incorrect application of the information of this publication. We reserve the right to make changes.

Properties

| Thickness D (mm) | 120 | 140 | 160 |

| Weight (kg/m2) | 13.1 | 13.9 | 14.6 |

| U-value (W/m2K) | 0.18 | 0.15 | 0.14 |

| Sound insulation Rw (dB) | 24 | 24 | 24 |

| Reaction to fire | B-s1, d0 | B-s1, d0 | B-s1, d0 |

| GWP-total, A1-A3 (kg CO₂ₑ/m²) | 32.6 | 34.2 | 35.8 |

| GWP-total, A1-A3 (kg CO₂e/m²) for Ruukki® LowCarbon | 19.9 | 21.5 | 23.1 |

| Wall fire resistance values & max span horizontal / vertical orientation (m): | 120 | 140 | 160 |

| EI 15 | 7.5 / 7.5 | 7.5 / 7.5 | 7.5 / 7.5 |

| EI 30 | 4.0 / 3.0* | 7.5 / 3.0* | 7.5 / 3.0* |

| EW 30 | 7.5 / 7.5 | 7.5 / 7.5 | 7.5 / 7.5 |

| EW 45 | - / 3.0 | - / 3.0 | - / 3.0 |

*Span length for EI30 of FM approved panels is 7.5 (vertical)

All properties are declared in accordance with EN 14509 and related standards.

Coatings and colors

Materials

| Facing | Coating | Gloss Level (GU) | Corrosivity category | UV resistance | Colours |

| External | GreenCoat Pural BT Satin | 20 | C4 | Ruv4-5 | RAL7035 (RR292), RAL9010 (RR126) |

| External | GreenCoat Pural BT Metallic | 40 | C4 | Ruv4 | RAL9006 (RR40), RAL9007 (RR41) |

| External | Polyester | 35 | C3 | Ruv2-3 | RAL1015 (RR807), RAL1021, RAL2003, RAL3000 (RR770), RAL3009 (RR29), RAL3013 (RR774), RAL5003 (RR4F8), RAL5005 (RR4A8), RAL5012 (RR408), RAL6011 (RR526), RAL6018 (RR5G8), RAL7015 (RR23), RAL7016 (RR288), RAL7035 (RR2B1), RAL7040 (RR287), RAL9002 (RR1G6), RAL9003 (RR106), RAL9006 (RR946), RAL9007, RAL9010 (RR1G5), Golden Oak |

| Internal | Polyester | 35 | C3 | - | RAL9002 (RR1G6), RAL9010 (RR1G5) |

| Internal | PVC laminate * | C4 | - | White |

*) optional material

UV resistance describes how well the coating is able to keep its original colour and gloss levels in accordance with EN10169. The higher the class, the better the resistance.

Corrosivity categories describe the outdoor climate conditions in accordance with EN12944. The higher the category, the more corrosive environment.

Primary colors

Complementary colors

Profile options

| Modular width | Facing | Profile options |

| 1100mm | External | L, L25, M |

| Internal | L25 | |

| 1000mm | External | L, L25, M |

| Internal | L25 |

Design tools

Traypan® software for designing sandwich panels

With TrayPan®, you can design metal faced sandwich panels made by Ruukki. A panel structure can be designed as a single- or multi-span construction. You can easily give, with a few parameters, both suction and pressure loads caused by the wind. The application also calculates the necessary fasteners.

Go to Traypan®

Download BIM objects to your desktop

ProdLib brings Ruukki products as BIM models directly to your desktop in 3D form for design programs AutoCAD, Autodesk Revit, Archicad and Tekla Structures. Product libraries compile all necessary design models and detailed drawings in one place. Library updates are automatically notified, so as a user you can be sure that your product information is constantly up to date. ProdLib can also be used as a standalone desktop application.

Go to BIM libraryTechnical documents

Here you can find all technical documents related to Ruukki's sandwich panels. Documents are organised by document type. Click to enter document library.

Certificates and approvals

Here you can find all certificates and approvals related to Ruukki's sandwich panels. Documents are organised by document type. Click to enter document library.

Visualization tool

Get inspired with our Sandwich Panel visualization tool

With our interactive Visualization tool for Ruukki sandwich panels, you can easily explore and customize the perfect combination for your building project.

Go to visualization tool

.tmb-250x190.jpg?sfvrsn=607438b5_1)