Products tailored for each customer

Ruukki Construction produces high-quality products tailored for each customer. We work in close cooperation with our customers. Ruukki is specialised in metals and produces components for its customers’ end products. We produce a wide variety of steel, aluminium and stainless steel profiles and we have long experience as a profiling specialist and robust workmanship competence.

Our strength lies in our efficiency — customers’ products and success are our top priorities.

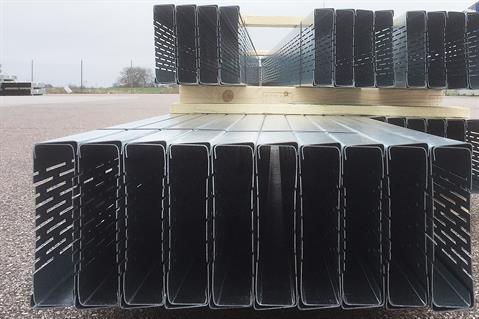

Anderslöv – profiling master

Ruukki Anderslöv is specialized in roll-formed metal and has produced profiles for customers’ products for almost 70 years. The factory’s product selection varies from 20-millimetre-long electronic parts to 18.5-metre-long roof profiles.

Because our production lines have a high repetition accuracy, our profiling produces premium products that guarantee the high quality of our customers’ products as well.

The Anderslöv factory has its own construction unit for producing tools that are used in the production lines. Having our own construction unit makes it possible to maintain a wide product selection. For customers, this means individually manufactured profiles without expensive added costs. Raw material is used in a way that does not cause waste, which means that all phases of the production chain are cost-effective.

From miniature profiles to giants

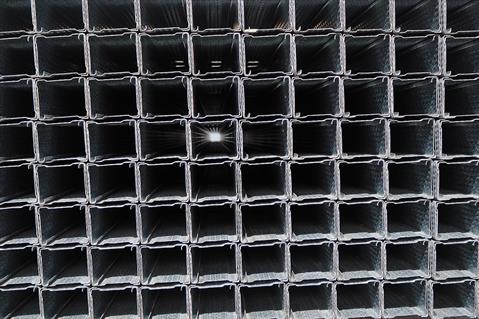

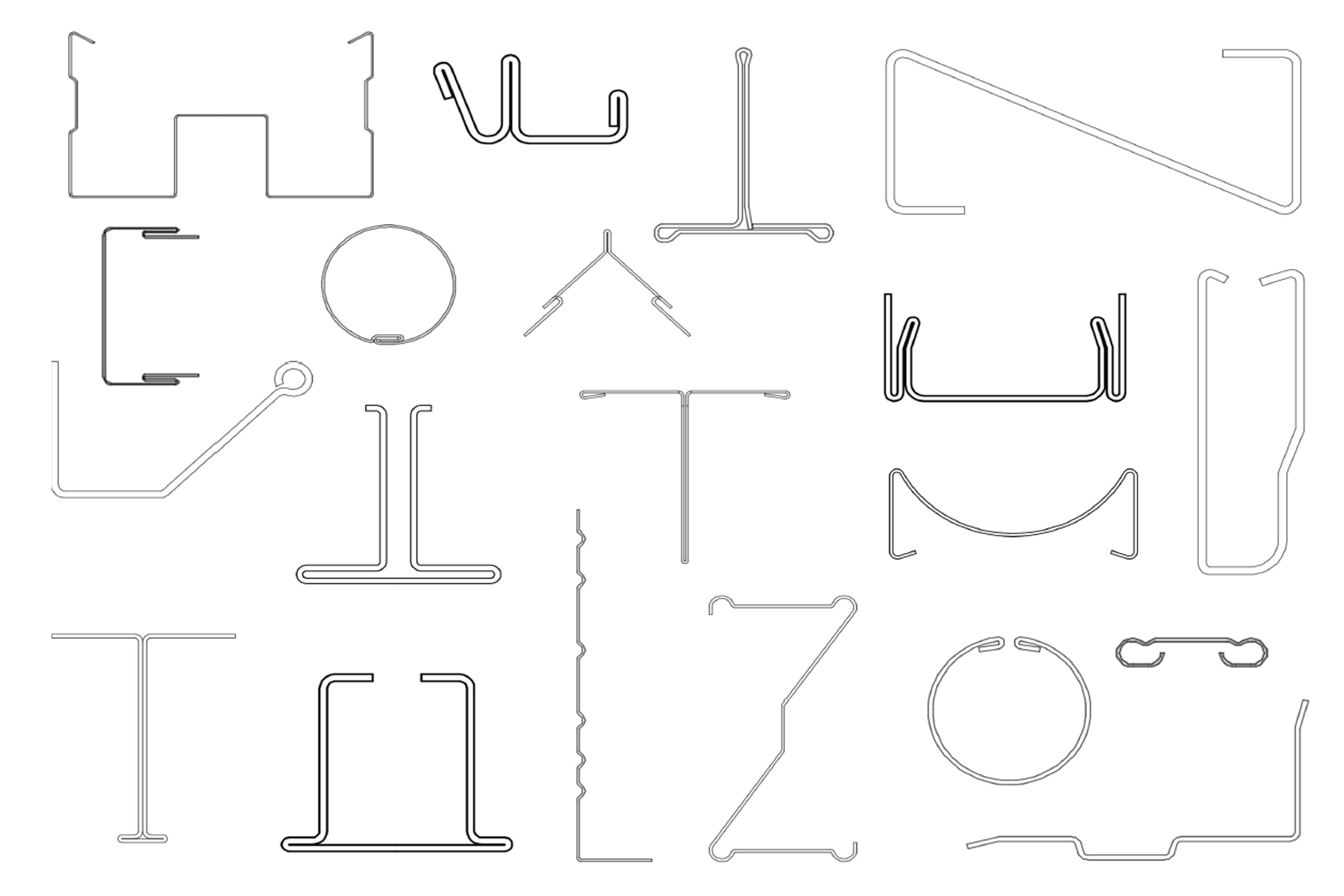

Our roll-profiling lines produce a large variety of profiles. Ruukki’s lowest profiles are 5 mm high, while the highest are 440 mm high.

To the left, some of our 1,200 low profile cross sections that we have created with our customers throughout the years.

What is roll forming?

Ruukki Anderslöv is specialised in roll forming where metal is profiled to the desired shape on our roll-forming lines. The rolling is carried out step-by-step in a continuous process with the tools forming the metal. The roll-forming line can even finalise the products, for example, by punching and installing the end product in a ready-made package.

Roll forming is well-suited for materials such as steel, aluminium and stainless steel. It’s also excellent for hard steel. Because high-strength steel products need less raw material, the material is used efficiently creating savings and environmental benefits.

Briefly about Anderslöv operations

The Anderslöv factory consists of more than 30,000 square meters of production premises with 23 profiling lines as well as a punching tool and bending line from Salvagnini. The factory has approximately 70 employees, and its markets include Sweden, Denmark, Norway, Finland, Western Europe and the US.

Here is what our customers are saying about us

Wall structure profiles

Components for roof elements

Contact us

Sending us a contact request form, you help us connect you with one of our Ruukki representatives or a trusted Ruukki partner, to whom we’ll forward your details. Please fill in the contact request form below, and you will hear from us as soon as possible. Required fields are marked with an asterisk (*).

Why we are collecting and processing personal data? Please check our Privacy Statement.

.tmb-250x190.jpg?sfvrsn=607438b5_1)