ALUMINIUM COMPOSITE

Aluminium composite (ACM)

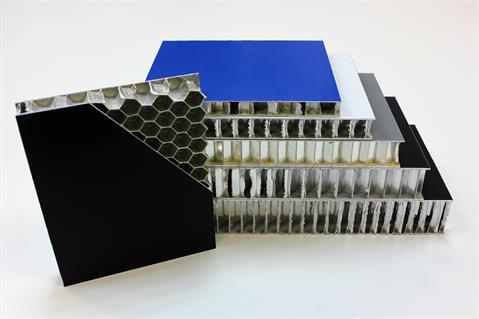

Colour-coated aluminum composite materials offer excellent surface flatness and enable big product sizes. Material consists of 2 aluminum facings bonded into inner core. Outer aluminum facing is PVDF painted with primer and colour coat. Aluminium composite materials are used in producing Ruukki Primo product family and they are available in three alternative core materials.

Aluminum composite material with light-weight honeycomb core

This innovative material consist of 0.7mm Aluminium facings bonded into inner honeycomb core made of Aluminium. Thanks to its low weight and high rigidity, this 14mm thick material is ideal for extra-large façade products. The material is used in producing Primo Skyline 1000 products, which are available in sizes up to 6200mm x 1900mm. The material has reaction to fire class A2-s1, d0, which makes it practically non-combustible and hence suitable for practically all building types. Due to honeycomb structure, the material cannot be perforated for outdoor use.

Aluminum composite material with solid A2 core

Material consist of 0.5mm Aluminium facings bonded into inner solid core made of mixture of minerals (90%) and polymers (10%). This 4mm thick material provides excellent surface flatness and is ideal for large façade products. The material is used in producing Primo Skyline 100 & 150 products, which are available in sizes up to 4000mm x 1000mm (Skyline 100) and 4000mm x 1400mm (Skyline 150) and in Primo Plana 10 product, which is available in size up to 4990mm x 1490mm. The material has reaction to fire class A2-s1, d0, which makes it practically non-combustible and hence suitable for practically all building types. Due to high mineral content in core, the material cannot be perforated for outdoor use and it’s not recommended for outdoor use in coastal areas (< 1500m from sea).

Aluminum composite material with solid FR core

Material consist of 0.5mm Aluminium facings bonded into inner solid core made of mixture of minerals (70%) and polymers (30%). This 4mm thick material provides excellent surface flatness and is ideal for large façade products. The material is used in producing Primo Skyline 100 & 150 products, which are available in sizes up to 4000mm x 1000mm (Skyline 100) and 4000mm x 1400mm (Skyline 150) and in Primo Plana 10 product, which is available in size up to 4990mm x 1490mm. The material has reaction to fire class B-s1, d0, which makes it material of limited combustibility and suitable for most of the building types. Due to lower mineral content in the core, the material can be perforated also for outdoor use.

Aluminium composite finishes - standard colours

Gloss level: 30 GU

| Surface treatment | Material | Corrosivity category | UV resistance | Minimum order quantity (m2) |

| PVDF | Aluminium composite FR* (Plana 10, Skyline 100 & 150) | C3 | Ruv4 | 150 |

| PVDF | Aluminium composite A2* (Plana 10, Skyline 100 & 150) | C3 | Ruv4 | 750 |

| PVDF | Aluminium honeycomb A2* (Skyline 1000) | C3 | Ruv4 | 1000 |

*FR: Reaction to fire class B-s1, d0

*A2: Reaction to fire class A2-s1, d0 (not recommended for coastal areas (<1500m from sea))

UV resistance describes how well the coating is able to keep its original colour and gloss levels in accordance with EN10169. The higher the class, the better the resistance.

Corrosivity categories describe the outdoor climate conditions in accordance with EN12944. The higher the category, the more corrosive environment.

Read more about corrosivity categories

Aluminium composite finishes - extended colour range

Gloss level: 30 GU

| Surface treatment | Material | Corrosivity category | UV resistance | Minimum order quantity (m2) |

| PVDF | Aluminium composite FR* (Plana 10, Skyline 100 & 150) | C3 | Ruv4 | 750 |

| PVDF | Aluminium composite A2* (Plana 10, Skyline 100 & 150) | C3 | Ruv4 | 750 |

| PVDF | Aluminium honeycomb A2* (Skyline 1000) | C3 | Ruv4 | 1000 |

*FR: Reaction to fire class B-s1, d0

*A2: Reaction to fire class A2-s1, d0 (not recommended for coastal areas (<1500m from sea))

UV resistance describes how well the coating is able to keep its original colour and gloss levels in accordance with EN10169. The higher the class, the better the resistance.

Corrosivity categories describe the outdoor climate conditions in accordance with EN12944. The higher the category, the more corrosive environment.

Read more about corrosivity categories

Aluminium composite finishes - other finishes

| Surface treatment | Material | Corrosivity category | UV resistance | Minimum order quantity (m2) |

| Holo coated aluminium | Aluminium composite FR* (Plana 10, Skyline 100 & 150) | C3 | Ruv4 | 750 |

| Holo coated aluminium | Aluminium composite A2* (Plana 10, Skyline 100 & 150) | C3 | Ruv4 | 750 |

| Holo coated aluminium | Aluminium honeycomb A2* (Skyline 1000) | C3 | Ruv4 | 1000 |

| Brushed aluminium | Aluminium composite FR* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

| Brushed aluminium | Aluminium composite A2* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

| Brushed aluminium | Aluminium honeycomb A2* (Skyline 1000) | C3 | n/a | 1000 |

| Bright aluminium | Aluminium composite FR* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

| Bright aluminium | Aluminium composite A2* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

| Bright aluminium | Aluminium honeycomb A2* (Skyline 1000) | C3 | n/a | 1000 |

| Textured aluminium | Aluminium composite FR* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

| Textured aluminium | Aluminium composite A2* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

| Textured aluminium | Aluminium honeycomb A2* (Skyline 1000) | C3 | n/a | 1000 |

| Design aluminium | Aluminium composite FR* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

| Design aluminium | Aluminium composite A2* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

| Design aluminium | Aluminium honeycomb A2* (Skyline 1000) | C3 | n/a | 1000 |

| Zinc | Aluminium composite FR* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

| Zinc | Aluminium composite A2* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

| Zinc | Aluminium honeycomb A2* (Skyline 1000) | C3 | n/a | 1000 |

| Copper & Brass | Aluminium composite FR* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

| Copper & Brass | Aluminium composite A2* (Plana 10, Skyline 100 & 150) | C3 | n/a | 750 |

*FR: Reaction to fire class B-s1, d0

*A2: Reaction to fire class A2-s1, d0 (not recommended for coastal areas (<1500m from sea))

UV resistance describes how well the coating is able to keep its original colour and gloss levels in accordance with EN10169. The higher the class, the better the resistance.

Corrosivity categories describe the outdoor climate conditions in accordance with EN12944. The higher the category, the more corrosive environment.

Read more about corrosivity categories

REFERENCES

Aluminium composite material in use

PRODUCT OFFERING

Facade cladding products available in aluminium composite material

- Product

- Description

-

Ruukki Primo Plana 10

- Minimum size: 200 x 200 mm

- Maximum size: 1490 x 4990 mm (free orientation)

- Depth: 4 mm

- Fasteners: visible

- Installation direction: Horizontal/Vertical

Ruukki® EmotionAvailable also with perforation and backlighting. -

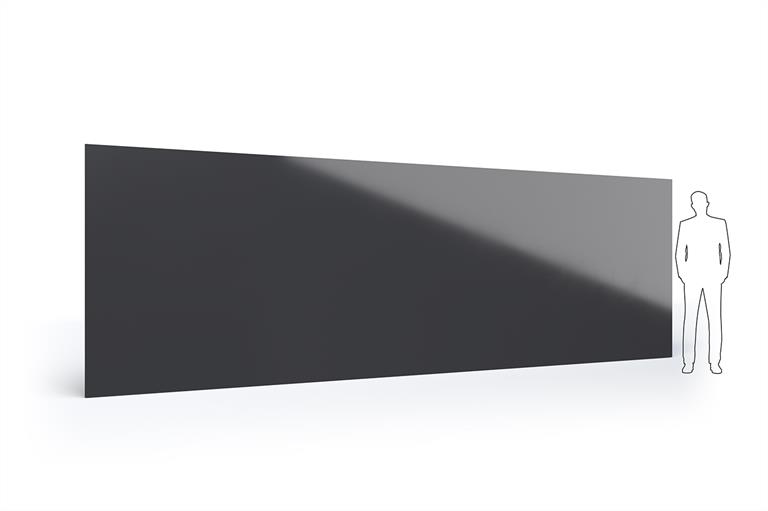

Ruukki Primo Skyline 1000

- Minimum size: 200 x 200 mm

- Maximum size: 6200 x 1900 mm (free orientation)

- Depth: 40 mm

- Fasteners: concealed

- Installation direction: Horizontal/Vertical

-

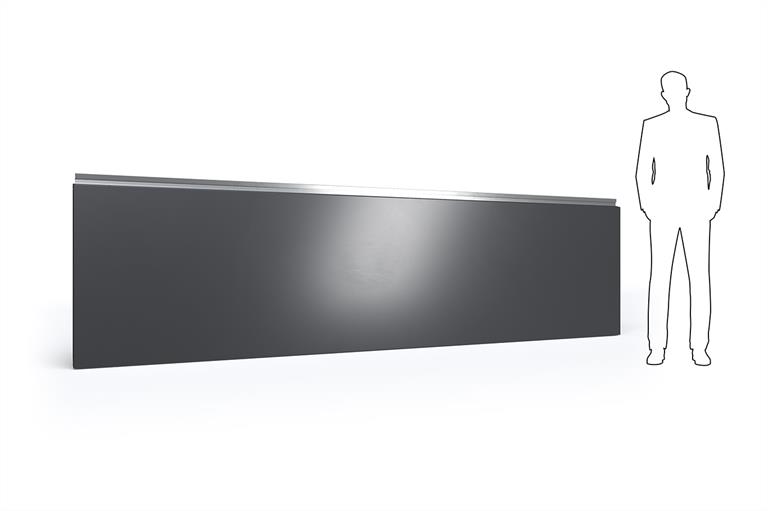

Ruukki Primo Skyline 150

- Width: 200...1400 mm

- Height: 200...4000 mm

- Depth: 40 mm

- Fasteners: concealed

- Installation direction: Vertical

Ruukki® EmotionAvailable also with perforation and backlighting. -

Ruukki Primo Skyline 100

- Width: 200...4000 mm

- Height: 200...1000 mm

- Depth: 40 mm

- Fasteners: concealed

- Installation direction: Horizontal

Ruukki® Emotion - Available also with perforation and backlighting.

CONTACT INFORMATION

Contact us

Getting in touch with us is easy. Just choose your country and we will help you look beyond what is - to what it could be!

CONTACT REQUEST

Why we are collecting and processing personal data? Please check our Privacy Statement.

Subscribe to our newsletter

Sign up for Ruukki Buildng Envelopes newsletter and stay informed with our latest news, offers and events.

Sign up hereOTHER MATERIALS

Facade cladding materials

Colour-coated steel

Colour-coated metal facade products are a durable way to use colours in all sizes of surfaces and colour compositions.

Read more about colour-coated materials.tmb-479v.jpg?sfvrsn=fd55b010_1)

Aluminium

Aluminium is a lightweight and highly corrosion resistant material available with colour-coating finish.

Read more about Aluminium material

Rheinzink

Patinated Rheinzink has an aesthetically soft, matt surface that gives a very natural impression. The patina changes very little over time.

Read more about Rheinzink materials

Stainless steel

Stainless steel maintains its shine and appearance very well and, as a solid material, it is very easy to maintain.

Read more about Stainless steel material

Aluminium composite

Colour-coated aluminum composite materials offer excellent surface flatness and enable big product sizes.

Read more about aluminium composite materials

Cor-Ten®

Cor-Ten® is a solid steel that has a natural, rugged patina that ages continuously in a unique way.

Read more about Cor-Ten® material

Copper, brass, bronze

Patina forming on the wall and various pre-patina options give these solid metals a live, genuine surface for very long time spans.

Read more about copper, brass and bronze materials

Glass

Glass creates a high gloss and durable flat surface for the facade.

Read more about Glass material

.tmb-250x190.jpg?sfvrsn=607438b5_1)