Building Envelope blog posts

Just on the borderline or punching well above the quality standard?

Jyrki Kesti & Risto Sipilä |

Can a construction product be too good? Is it enough for a product to just meet the requirements of EN standards? At Ruukki’s product development, we know a product through and through, and the requirements for the raw materials and manufacturing of products are set so that a product lasts longer even when a standard does not require a particular property.

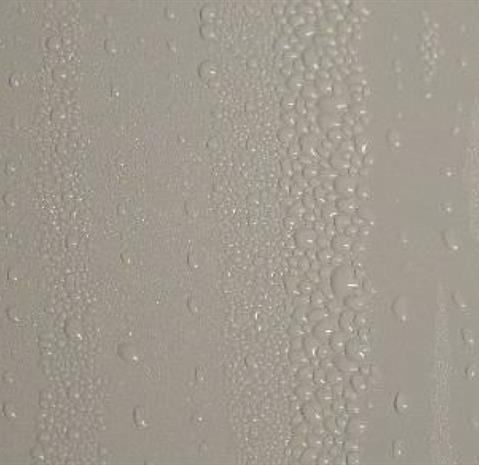

The reverse side coating of the steel sheets of mineral wool insulation panels is a good example of punching above the standards and the benefits it brings. The four-step classification under the European standard places the condensation resistance of this coating in the lower category. In fact, this coating is out of sight, but Ruukki requires the top classification for its own products to ensure that sandwich panels are reliable and lasting building products also in the event of any disruptions. These disruptions include, for example, the structures getting wet during the construction phase, carelessly done seams or leaks caused by inlet ducts.

Changing climatic conditions will increase rainfall and put greater strain on wall structures than anticipated. Ruukki commissioned an extended standard test for reverse side coatings at Häme University of Applied Sciences. Normally, if the surface of the coating remains almost flawless after 500 hours of condensation test, it exceeds the classification required by the standard. Ruukki continued testing for 9,600 hours, more than a year, which is more than six times longer than the top classification requires. Even then, the surface of the reverse side coating of the sample tested was completely flawless. The EN standard has no adhesion requirements whatsoever for the reverse side coating used for galvanized steel. The adhesion of the reverse side coating of Ruukki products remained excellent even after the 9,600-hour test. This gives us strong support to tell about the durability of our products.

The product property described above is a requirement for panels made at the Alajärvi plant in Finland for tough Nordic conditions.

.tmb-250x190.jpg?sfvrsn=607438b5_1)