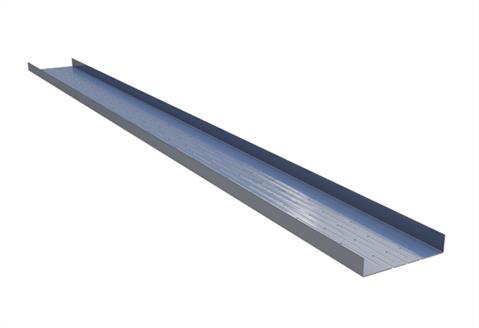

U Purlin, Termo

Ruukki’s Termo purlins offer an optimised solution for avoiding cold bridges in purlin constructions on external roofs or walls.

Cold bridges can be minimised by the slotted hole system on the purlins’ web. To optimise the design, use our PurCalc software.

Applications:

- Industrial construction

- Hall and warehouse construction

- Renovation projects

The information on our website is accurate to the best of our knowledge and understanding. Although every effort has been made to ensure accuracy, the company cannot accept any responsibility for any direct or indirect damages resulting from possible errors or incorrect application of the information of this publication. We reserve the right to make changes.

Properties

Hot galvanized steel sheet. Steel quality S350GD+Z275 according to EN 10346.

Applications in environments with corrosivity: C2 according to the EN ISO 12944-2.

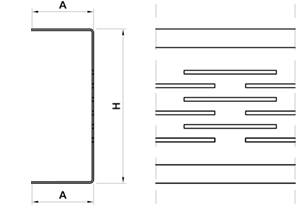

Cross section geometries: Termo Purlin U

| Type of purlin | Termo perforation row quantity (pcs) | Extra conductance (W/mK) | Thickness (mm) | H (mm) | A (mm) | B (mm) | C (mm) | Weight (kg/m) |

| LPT-U100 | 8 | 0,023 | 1 | 100 | >=50.0 | - | - | 1.86 |

| 0,025 | 1.2 | 2.23 | ||||||

| 0,028 | 1.5 | 2.79 | ||||||

| LPT-U154 | 8 | 0,024 | 1 | 154 | >=48.0 | - | - | 1.89 |

| 0,026 | 1.2 | 2.27 | ||||||

| 0,029 | 1.5 | 2.84 | ||||||

| 0,034 | 2 | 3.78 | ||||||

| LPT-U175 | 8 | 0,025 | 1 | 175 | >=48.0 | - | - | 2.02 |

| 0,027 | 1.2 | 2.42 | ||||||

| 0,030 | 1.5 | 3.03 | ||||||

| LPT-U179 | 8 | 0,025 | 1 | 179 | >=46.0 | - | - | 2.05 |

| 0,027 | 1.2 | 2.46 | ||||||

| 0,030 | 1.5 | 3.07 | ||||||

| LPT-U200 | 8 | 0,026 | 1 | 200 | >=48.5 | - | - | 2.21 |

| 0,028 | 1.2 | 2.66 | ||||||

| 0,031 | 1.5 | 3.32 | ||||||

| LPT-U204 | 8 | 0,026 | 1 | 204 | >=46.5 | - | - | 2.25 |

| 0,028 | 1.2 | 2.69 | ||||||

| 0,031 | 1.5 | 3.37 | ||||||

| LPT-U229 | 8 | 0,027 | 1.0 | 229 | >=47.5 | - | - | 2.44 |

| 0,029 | 1.2 | 2.93 | ||||||

| 0,032 | 1.5 | 3.66 | ||||||

| LPT-U250 | 10 | 0,022 | 1 | 250 | >=50.0 | - | - | 2.65 |

| 0,024 | 1.2 | 3.17 | ||||||

| 0,027 | 1.5 | 3.97 | ||||||

| LPT-U254 | 10 | 0,022 | 1 | 254 | >=48.0 | - | - | 2.68 |

| 0,024 | 1.2 | 3.21 | ||||||

| 0,027 | 1.5 | 4.02 |

Design tools

PurCalc® software for designing purlins

With the PurCalc® software, the user can design roof and wall purlins produced by Ruukki. The purlins are designed as continuous beams. The purlin type must be the same for the whole structure, but the thickness may vary. One of the purlin flanges is assumed to be supported with the profile sheet. The other flange may be either supported or unsupported. Basic loads such as uniform snow load and wind load can be easily given with a few parameters. Also, more complicated load types, such as snowdrift loads, can be given. The software calculates the necessary fasteners for the supporting structure as well.

Go to PurCalc® software

Download BIM objects to your desktop

ProdLib brings Ruukki products as BIM models directly to your desktop in 3D form for design programs AutoCAD, Autodesk Revit, Archicad and Tekla Structures. Product libraries compile all necessary design models and detailed drawings in one place. Library updates are automatically notified, so as a user you can be sure that your product information is constantly up to date. ProdLib can also be used as a standalone desktop application.

Go to BIM libraryOrdering

Please provide the following information when ordering:

- Type of purlin

- Thickness

- Length

- Number.

In case of pre-punched purlins, please send us purlin drawings showing the location of the holes.

Pre-punching service

Purlins can be pre-punched in our factory. This makes construction on-site faster and easier. The standardised sizes and locations of holes for fixing screws are presented below. Please contact us for additional information about the pre-punching possibilities.

Holes are made during production at continuous line.

Additional information:

- Max. material thickness 3mm (for ø 60mm max. material thickness 2mm)

- Holes can be made in a row

- Oval and rectangular holes can be rotated by 90°.

| Type of hole | Diameter (mm) | Rotation (°) |

| Round | 7 | - |

| Round | 10 | - |

| Round | 12 | - |

| Round | 14 | - |

| Round | 16 | - |

| Round | 18 | - |

| Round | 20 | - |

| Round | 22 | - |

| Round | 26 | - |

| Round | 60 | - |

| Oval | 12×24 | 90 |

| Oval | 14×24 | 90 |

| Oval | 16×35 | 90 |

| Oval | 18×31.7 | 90 |

| Oval | 18×35 | 90 |

| Oval | 20×35 | 90 |

| Rectangular | 5×25 | 90 |

Technical documents

Here you can find all technical documents related to Ruukki's light weight purlins. Documents are organised by document type. Click to enter document library.

Certificates and approvals

Here you can find all certificates and approvals related to Ruukki's light weight purlins. Documents are organised by document type. Click to enter document library.

.tmb-250x190.jpg?sfvrsn=607438b5_1)