From furniture manufacturing to becoming a leader in steel roll forming and an important part of Ruukki Construction – much has happened at the Anderslöv plant in Sweden since it was established 75 years ago. “Even though the focus of operations has shifted over time, the plant has always played an important role for the local community. Generations of people from Anderslöv have worked here, and there has always been loyalty and pride in what we achieve,” says Plant Manager Lars-Göran Kristiansson, who has been part of Anderslöv’s journey since 1984.

Driven by innovation, openness to renewal, and strong craftsmanship, Ruukki’s Anderslöv facility has developed into a leader in steel roll forming. Today, its specialist expertise includes the production of customer-specific products and solutions.

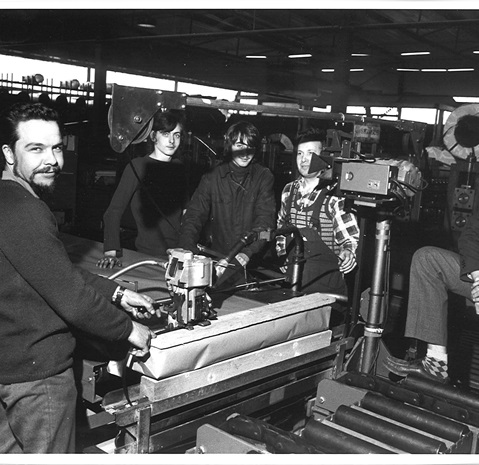

The factory has carried many names and owners since its foundation in 1950, when it was established by Sweden’s then largest furniture manufacturer, Thysells Möbler, under the name Thysells Industri. Over time, operations expanded into sheet metal processing, producing slats for blinds. In the mid-1960s, a collaboration with Gyproc began – a partnership that continues to this day.

“One proof of the quality of our products and our ability to quickly solve customer needs is our long customer relationships, which we are proud of and which in many cases have lasted for decades,” says Lars-Göran Kristiansson, who after 41 years at Anderslöv knows the plant’s history inside out.

When the focus shifted to steel roll forming, the furniture production was gradually discontinued. In the decades that followed, the plant was owned by companies including Ahlsell, Boliden, and Trelleborg, until it was acquired in 1991 by Rautaruukki – today Ruukki Construction. The integration was further strengthened in 2005 when the plant was renamed Ruukki Anderslöv.

High ambitions in production and environment

A key reason why the Anderslöv operations have not only survived but also grown into a leading position in steel roll forming is the deep technical knowledge, curiosity, and hands-on approach that characterizes the work.

“One of our strengths and success factors is our ability – in addition to our wide standard assortment of steel profiles – to quickly and efficiently produce and deliver customer-specific solutions. This is made possible by our in-house design department for tool development for the production lines,” explains Kristiansson.

The plant also has high ambitions in environmental performance. Ruukki’s group target is to reduce direct and indirect energy-related emissions from its own operations by 85% by 2035, compared with 2019. In Anderslöv, this target has already been reached thanks to measures such as switching to non-fossil energy sources, using green electricity for heating, and biodiesel instead of fossil fuel for forklifts. As part of SSAB, Ruukki can also now offer SSAB Zero recycled steel. Using SSAB Zero in products can cut emissions by up to 68% compared with conventional steel. Steel’s high recyclability, long service life, and low environmental impact make it a material of the future – contributing to circular construction and lower CO₂ emissions.

Preparing Anderslöv for the next chapter

Kristiansson is not the only one with decades of experience at the Anderslöv plant. Several families have worked there across generations. One example is Sales Engineer Jerry Hansson, who first joined as a summer worker more than 30 years ago. After working for other employers, he always returned – just like his brother and father who also worked at the plant.

“Steel is my life,” he says.

Today, Kristiansson’s focus is on preparing Anderslöv for the future, including investments in machinery and competence to continue offering advanced and often customized products.

“We are facing a generational shift in the coming years, and my job is to ensure the organization is ready to write the next chapter in the plant’s history together with a new generation. The passion for technology and development, combined with the strong teamwork and sense of responsibility among our employees, must be preserved to remain relevant in the future,” he says.

On September 12, Anderslöv’s 75th anniversary was celebrated with an event for current and former employees. Customers, who were invited for a plant tour, also took part.

Ruukki Construction’s Anderslöv plant, part of the global steel company SSAB, has 30,000 m² of production space with 23 roll forming lines plus punching and bending lines. Each year, 25,000 tons of steel and 550 tons of aluminum are processed into profiles for wall structures and components for roof elements. The plant employs around 75 people and delivers products mainly to the Nordics, but also to other parts of Europe and the USA.

.tmb-250x190.jpg?sfvrsn=607438b5_1)