Low on carbon footprint. High on sustainability.

"The construction world has a major responsibility toward paving the path for a carbon-neutral future for the industry. Everything from the choice of raw materials and products used in buildings, logistics, construction processes and building use-phase inevitably has a huge impact on the environment. We offer a wide portfolio of low carbon solutions that can reduce environmental impact by helping you create cleaner, greener and more sustainable built environment."

Jyrki Kesti, Head of Sustainability Development, Building Envelopes

Towards carbon-neutral building products

When you look at the complete lifecycle of a building, it is important to evaluate the total carbon emissions of all building materials and products and the construction process — known as the building’s embodied carbon. We work systematically towards reducing the environmental impact of our products by not only minimizing embodied carbon emissions today, but also considering the future emissions impacts during the product’s lifecycle — durability, longevity, end-of-life scenarios, reusability, and recyclability.

Fossil free steel as an enabler

SSAB , LKAB (Europe’s largest iron ore producer) and Vattenfall (one of Europe’s largest energy companies) have joined forces in HYBRIT. Using HYBRIT technology, SSAB aims to replace coking coal, traditionally needed for ore-based steelmaking, with fossil-free electricity and hydrogen. The result will be the world’s first fossil-free steelmaking technology, with virtually no carbon footprint. Goal is to reduce Sweden’s CO2 emissions by 10 % and Finland’s by 7 %.

We in Ruukki will be the first in line to utilize this revolutionary fossil free steel in building products from 2026.

Opting for low CO2 and circular raw materials to reduce environmental impact

Already today, we are focusing on low carbon and circular raw materials in our products to offer low-carbon products to our customers.

- Our parent company SSAB’s color-coated steel has about a 15 % lower carbon footprint than the global average

- Over 70 % of the weight of Ruukki Life panel insulation is made of recycled glass

- Our own PIR-formulation contains a raw material that uses 50 % recycled PE

Optimizing processes to reduce carbon footprint

We aim to reduce the carbon footprint of our own operations by 70 % by the year 2030 compared to 2019 — we are almost getting there through deliberate action in our everyday processes:

- Optimizing material usage in our products — less weight equals less CO2 emissions and less energy during transportation and installation

- Most of our plants have shifted to zero-emission electricity

- Half of our plants have already switched to electric and bio-diesel forklift trucks

- Opting for bio-based fuel – already implemented in Sweden

- Improving the energy efficiency of buildings at all our plants

- Investing in on-site solar power generation – first installations in Poland

- Reducing steel and insulation waste during manufacturing by optimizing production and product sizes — we have achieved a 30% improvement in our panel factory in Finland

- Choosing lower-emission packaging materials and optimizing the weight of the packaging — weight of wooden pallets already reduced, plastic usage under research

"We are proud of our process development and energy efficiency actions in Oborniki factory in Poland. For example, our smart solutions in the new mineral wool panel line directly contribute to our carbon neutral targets. With new production technology, we can use thinner slabs and thus decrease the amount of wool dust at the milling station. We use less energy to ensure proper temperature conditions for the production process and we have introduced new ways of waste management, such as press compactors for wool scrap that reduce its volume and lower transportation costs. We effectively reuse panel core’s scrap as a raw material for new products."

Marcin Remisz, Production Manager, Oborniki plant

Prioritizing greener alternatives to enable cleaner logistics

- Our production plants are located near our customers to minimize transportation emissions. For example, we have recently informed on new PIR panel production line in Sweden to be close to our Nordic customers.

- Improving logistics efficiency — ensuring full loads and optimizing return loads delivering raw materials to the factory

- Actively seeking green logistic solutions together with our contract transportation companies

Optimized solutions that guarantee most sustainable buildings

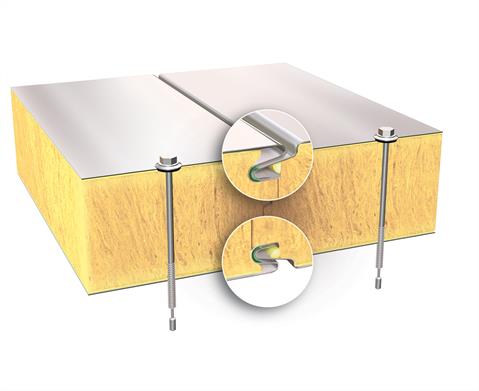

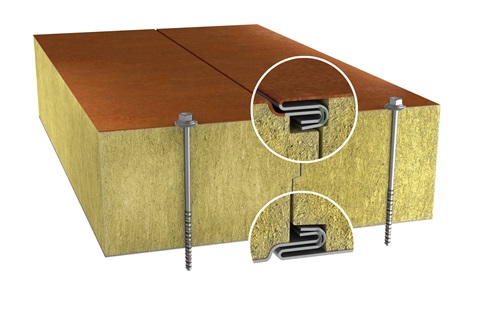

Examples of our low carbon products

Focusing on reusability, renewability and end-of-life optimization

- Our superior coating solutions with product warranties guarantee long service life to the products without product changes and minimized maintenance needs, or even maintenance free such as Ruukki® Patina Panel

- Most of our products also enable reusing if the building life span is less than the product service life. This means remarkable CO2 savings in the following life cycles

- Preservation of steel’s inherent properties after recycling classifies them as “permanent materials"

Learn more about our life-cycle approach, documentation and solutions

Interested in our low carbon products? Please fill in the form and we will contact you!

Sending us a contact request form, you help us connect you with one of our Ruukki representatives or a trusted Ruukki partner, to whom we’ll forward your details. Please fill in the contact request form below, and you will hear from us as soon as possible. Required fields are marked with an asterisk (*).

Why we are collecting and processing personal data? Please check our Privacy Statement.

.tmb-250x190.jpg?sfvrsn=607438b5_1)

.tmb-479v.jpg?sfvrsn=5857042c_1)