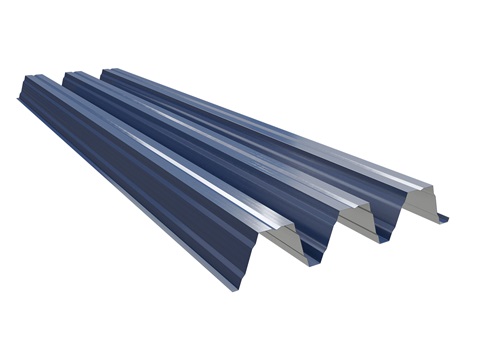

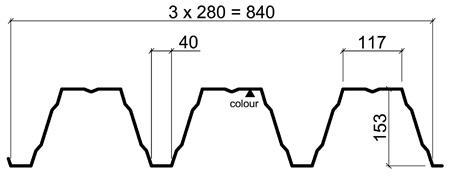

Load-Bearing Sheet T153-40L-840

Height and optimal geometry of the T153 makes it the strongest load-bearing sheet in our portfolio.

This product is optionally available with following sustainable features:

- Steel profile made of recycled steel (SSAB Zero) for significantly lower CO2 emissions and high circularity (Ruukki LowCarbon)

- Availability and delivery time for different thickness/coating combinations varies.

For the optimal structural dimensioning, use Ruukki’s roof dimensioning software, Poimu.

The information on our website is accurate to the best of our knowledge and understanding. Although every effort has been made to ensure accuracy, the company cannot accept any responsibility for any direct or indirect damages resulting from possible errors or incorrect application of the information of this publication. We reserve the right to make changes.

Properties

Materials

Materials

| Material thickness (mm) | Steel grade | Zinc (g/m2) | Surface treatment | Corrosion class, interior | Corrosion class, exterior | Colours ** | Weight (kg/m2) | GWP, A1-A3 (kgCO2e/m2) | GWP, D (kgCO2e/m2) | LowCarbon GWP, A1-A3 (kgCO2e/m2) |

| 0.7 | S350 | Z275 | Galvanized | C2 | - | - | 9.81 | 25.5 | -13.8 | 8.1 |

| 0.7 | S350 | Z100 | Polyester 25 | C2 | - | RR20 | 9.81 | 26.9 | -13.8 | 11.0 |

| 0.7 | S350 | Z275 | Polyester 25 | C3* | C3 | RR20 | 9.81 | 26.9 | -13.8 | 11.0 |

| 0.8 | S350 | Z275 | Galvanized | C2 | - | - | 11.22 | 29.1 | -15.8 | 9 |

| 0.8 | S350 | Z275 | Polyester 25 | C3* | C3 | RR33 | 11.21 | 30.7 | -15.8 | 12.6 |

| 0.8 | S350 | Z100 | Polyester 25 | C2 | - | RR20 | 11.21 | 30.7 | -15.8 | 12.6 |

| 0.9 | S350 | Z275 | Galvanized | C2 | - | - | 12.62 | 32.8 | -17.8 | 10.4 |

| 0.9 | S350 | Z100 | Polyester 25 | C2 | - | RR20 | 12.62 | 34.6 | -17.8 | 14.1 |

| 1.0 | S350 | Z275 | Galvanized | C2 | - | - | 14.02 | 36.5 | -19.8 | 11.6 |

| 1.0 | S350 | Z100 | Polyester 25 | C2 | - | RR20 | 14.02 | 38.4 | -19.8 | 15.7 |

| 1.0 | S350 | Z275 | Polyester 25 | C3* | C3 | RR20, RR33 | 14.02 | 38.4 | -19.8 | 15.7 |

| 1.0 | S350 | Z275 | GreenCoat Pural BT | C4* | C4 | RR23 | 14.02 | 38.4 | -19.8 | 15.7 |

| 1.2 | S350 | Z275 | Galvanized | C2 | - | - | 16.82 | 43.7 | -23.7 | 13.9 |

| 1.2 | S350 | Z100 | Polyester 25 | C2 | - | RR20 | 16.82 | 46.1 | -23.7 | 18.8 |

| 1.2 | S350 | Z275 | Polyester 25 | C3* | C3 | RR33 | 16.82 | 46.1 | -23.7 | 18.8 |

| 1.5 | S350 | Z275 | Galvanized | C2 | - | - | 21.03 | 54.7 | -29.7 | 17.4 |

| 1.5 | S350 | Z100 | Polyester 25 | C2 | - | RR20 | 21.03 | 57.6 | -29.7 | 23.6 |

*) For perforated sheetings C2

**) The reverse sides of the colour coated sheets are painted as standard with 2-layer grey backside coating

Protection against corrosion

| Environment | Coating |

| Interior applications in environments with corrosivity category C1, C2 according to EN ISO 12944-2 standard and A1, A2 according to EN 10169 standard | Steel sheets with zinc coating of 100 g/m2 and with polyester coating SP 15, thickness 15 μm |

| Interior applications in environments with corrosivity category C1, C2, C3 according to EN ISO 12944-2 standard and A1, A2, A3 according to EN 10169 standard | Steel sheets with zinc coating of 275 g/m2 and with polyester coating SP 25, thickness 25 μm |

Design tools

Poimu software for dimensioning load-bearing sheets

Dimensioning software, Poimu, allows you to optimise product choice according to the Eurocode. Simply by defining some basic input data you can select a load-bearing sheet for their needs from Ruukki's selection. This quick optimisation tool covers 1-, 2-span and continuous structures and gives the exact solution as to what sheet should be used, as well as its length.

Go to Poimu software

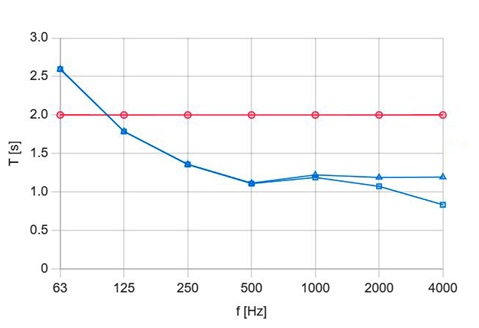

Ruukki Acoustic Estimator

Try our estimator for your next project. With our estimation tool you can calculate which product configuration provides you with optimal results.

Go to estimation tool hereAcoustic perforation

Acoustic absorption coefficient, absorption class and sound insulation

Find detailed acoustic information from https:/www.ruukki.com/sound-environment where is collection of products, guide and measured values are available.

Corrosion resistance

Due to requirement regarding corrosion resistance perforated steel sheets may be applied only indoors and as follows:

Galvanized steel sheets with zinc coating 275 g/m2 or galvanized steel sheets with zinc coating 100 g/m2 or 275 g/m2 together with organic coating SP 25 (polyester 25 µm) - in corroding medium C1 and C2 as per EN ISO 12944-2.

Load bearing profile application

Load bearing profiles are usually applied in multi layer roofing constructions. Sound absorption can be improved and adjusted by profile perforation selection and insulation layer selection. Perforation leads to improved sound absorption that can greatly improve indoor acoustic conditions; reduction of sound reverberation time and background noise level even without extra acoustic layers and involved costs.

Use of POIMU software enables trapezoidal sheets within a structure to be dimensioned and optimized with perforated profiles too. For more information on POIMU visit Ruukki Design Tools.

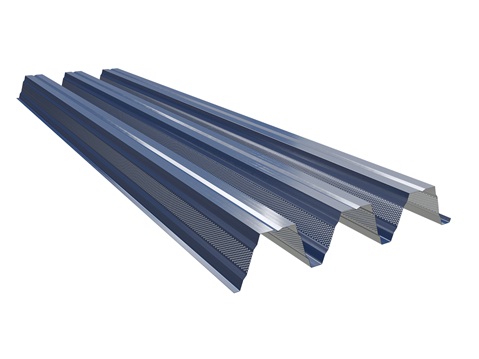

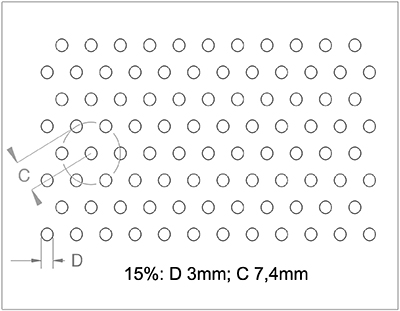

Perforation pattern

Standard degree of perforation is 15% within the area perforated for web perforated profiles.

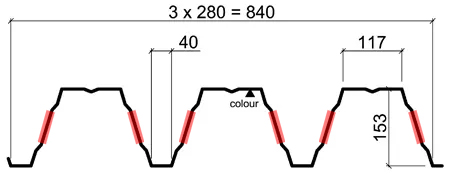

|

Perforation location for T153 profile marked with red.

Anticondensation layer

Profiles with anti-condensation layer are protected against water condensation directly at the bottom surface of the metal sheet. The layer absorbs water which then may be evaporated into the surrounding environment during a change in weather conditions.

Perlite coat, sprayed only on the bottom surface (back coating side) of the profile.

| Layer weight | 400 …. 1 000 g/m2 |

| Water-absorption capacity | ~0.5–0.8 l/m2–1.1–1.5 l/m2 |

| Coating method | Sprayed |

| Colour | Light gray |

| Diluting agent | Water |

| Composition | Perlite grains, cellulose fibres, water and binder |

Technical documents

Here you can find all technical documents related to Ruukki's load-bearing sheets. Documents are organised by document type. Click to enter document library.

Certificates and approvals

Here you can find all certificates and approvals related to Ruukki's load-bearing sheets. Documents are organised by document type. Click to enter document library.

.tmb-250x190.jpg?sfvrsn=607438b5_1)